Scientific 20MM Co-Rotating Twin-Screw Extruder

Available in High Corrosion Resistant as well as High Wear Resistant versions

NEW Maxi20Compounder with 11 KW Drive

The Scientific 20 mm co-rotating twin-screw extruder is the ideal laboratory extruder for production of smaller batches, be it for experimental purpose or for producing samples to your customer.

The Scientific 20 mm co-rotating twin-screw extruder is the ideal laboratory extruder for production of smaller batches, be it for experimental purpose or for producing samples to your customer.

This twin-screw is built up exactly in the same way as our larger 26 mm version, comprising of a complete modular build up of the clam-shell barrel, where each barrel section have a length of 4 D or 80 mm. Many standard lengths are available from 32 to 52 L/D and even longer on request. Also two drive powers are now available of 5.5 and 11 kW.

The modular Clam-shell Barrel is supplied as standard in the high temperature versions and it is equipped with exchangeable barrel lining inserts for optimum economy and ease of replacement. These standard inserts are made from a high grade tool steel which is through hardened to over 60 RC as well as nitrided for a surface hardness of 65 to 70 RC. The barrel with inserts can withstand high processing temperatures of up to 400 °C.

The screws are built up from single individual elements mounted on hexagonal hardened shafts. Each individual kneading elements is supplied in many angles to enable optimum variations in screw configurations. The screw components are made from high-grade tool steel which is through-hardened but made with a slightly softer hardness than the barrel linings to ensure optimum lifetime for both elements and barrel inserts.

The screws are built up from single individual elements mounted on hexagonal hardened shafts. Each individual kneading elements is supplied in many angles to enable optimum variations in screw configurations. The screw components are made from high-grade tool steel which is through-hardened but made with a slightly softer hardness than the barrel linings to ensure optimum lifetime for both elements and barrel inserts.

The whole clamshell barrel assembly is split in the center and can be easily swung open after loosening the barrel bolts. This gives easy access to the screws for cleaning or changing of screw elements and/or barrel inserts as well as to observe the melt and compounding characteristics of the polymer being processed. The top half of the barrel is balanced, so that very little force is needed to open it up and with this, the hazard of accidental heavy closing is eliminated.

Each barrel zone is equipped with both water cooling and electric cartridge heating. This allows for complete process control at each zone of the barrel and the water cooling coupled with the high wattage heating enables fast temperature changes of each zone when changing processing conditions from one compound to another. The water cooling is done from fine channels inside each barrel module and regulated with individual solenoid valves from its designated temperature controller

NEW Maxi20Compounder

The 20 mm twin is now available in high output, high torque version which has a drive power of 11 kW and a max screw RPM of 1200. This version is equipped with our high torque gear design which has an additional supporting gear shaft. It is also equipped with forced lubrication by an external oil gear pump coupled to a large plate-type oil cooler.

The 20 mm twin is now available in high output, high torque version which has a drive power of 11 kW and a max screw RPM of 1200. This version is equipped with our high torque gear design which has an additional supporting gear shaft. It is also equipped with forced lubrication by an external oil gear pump coupled to a large plate-type oil cooler.

The extruder is also, as standard, equipped with a two holes strand die mounted on a hinged flange and connected to the barrel with two bolts. The barrel end part is also equipped with an easily removable breaker plate which enables production either with or without screen packs. The strand die is our new short version, which is very easy to clean and is ideal for short runs with frequent color changes etc. An adaptor with C-clamp can be supplied to replace the flanged strand die in case the extruder is to be used with our other downstream equipment such as chill roll line etc.

The extruder can optionally be equipped with one or more twin screw side feeders which are connected to the side of the barrel module. A special barrel module with opening as well as plug for side feeder is needed for this option, and the extruder can be supplied with several plugged side feeder modules for optimum flexibility of side feeder location. The side feeder has an infinitely variable speed drive with 20 mm diameter twin screws and with an L/D ratio of 10. The entire barrel of the side feeder is equipped with water cooling as standard

The extruder can optionally be equipped with one or more twin screw side feeders which are connected to the side of the barrel module. A special barrel module with opening as well as plug for side feeder is needed for this option, and the extruder can be supplied with several plugged side feeder modules for optimum flexibility of side feeder location. The side feeder has an infinitely variable speed drive with 20 mm diameter twin screws and with an L/D ratio of 10. The entire barrel of the side feeder is equipped with water cooling as standard

The extruders are supplied complete with a stainless steel volumetric hopper feeder with a single feed screw and with a stirring arm (agitator) above the feeding screw. The hopper feeder can optionally also be equipped with twin screws. The screw is driven by variable speed AC gear motor of 0.3 kW power and digital screw speed control mounted on the control cabinet.

The 32 L/D extruder is, as standard, supplied with a single venting zone on one of the barrel modules. However, the 40 L/D and longer versions are supplied as standard with two venting zones where one vent zone is equipped with vacuum, and the other is used for atmospheric venting. It is also possible to use both vent openings for vacuum venting.

The 32 L/D extruder is, as standard, supplied with a single venting zone on one of the barrel modules. However, the 40 L/D and longer versions are supplied as standard with two venting zones where one vent zone is equipped with vacuum, and the other is used for atmospheric venting. It is also possible to use both vent openings for vacuum venting.

The vacuum venting system is supplied with one stainless steel vent port housing which is equipped with a sight glass on the open swing lid and a vacuum regulator valve with gauge. The vent housing is made with a resin trap to prevent that any resin leaking in the vent will plug the pipes to the vacuum pump. The housing is connected to twin large vacuum filters and a vane type vacuum pump mounted in the sub cabinet.

The vacuum venting system is supplied with one stainless steel vent port housing which is equipped with a sight glass on the open swing lid and a vacuum regulator valve with gauge. The vent housing is made with a resin trap to prevent that any resin leaking in the vent will plug the pipes to the vacuum pump. The housing is connected to twin large vacuum filters and a vane type vacuum pump mounted in the sub cabinet.

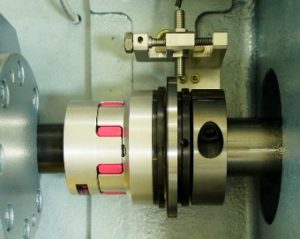

All of the 20 mm twin screw extruder versions have a powerful 5.5 KW drive motor equipped with a torque limiter which will instantly disengage the coupling to the motor in the event that the screws are overloaded. The torque limiter is also equipped with a sensor which will stop the motor and a warning lamp on the control panel will indicate that the screws have been overloaded.

The extruder can optionally be equipped with one or more twin screw side feeders which are connected to the side of the barrel module. A special barrel module with opening as well as plug for side feeder is needed for this option, and the extruder can be supplied with several plugged side feeder modules for optimum flexibility of side feeder location. The side feeder has an infinitely variable speed drive with 20 mm diameter twin screws and with an L/D ratio of 7. The entire barrel of the side feeder is equipped with water cooling as standard.

The extruder can optionally be equipped with one or more twin screw side feeders which are connected to the side of the barrel module. A special barrel module with opening as well as plug for side feeder is needed for this option, and the extruder can be supplied with several plugged side feeder modules for optimum flexibility of side feeder location. The side feeder has an infinitely variable speed drive with 20 mm diameter twin screws and with an L/D ratio of 7. The entire barrel of the side feeder is equipped with water cooling as standard.

Summary of Standard Features

- All inserts are also available with high wear resistant HIP steel type as well as with medium corrosion-resistant steel type SUS440C and in Very High corrosion-resistant M390 steel.

- The standard screw and kneading elements are also made from high-grade tool steel with through hardening and with a surface hardness of slightly below the hardness of the barrel inserts. Also, the hexagonal screw shafts are made of treated tool steel for optimum stiffness and high torque applications.

- Water cooling as well as electric heating of each barrel module

- Standard drive with gearbox designed for screw speeds up to 800 RPM and motor power of 5.5 kW. With torque limiter on the motor drive coupling to protect screws from overloading.

- NEW Maxi20compounder with high torque forced lubricated gearbox and 11 kW drive. Made for high output with screw RPM of up to 1200.

- Stainless steel vent housing on the barrel equipped with sight glass and vacuum gauge as well as vacuum pump protected with large dual filters coupled in series and mounted in sub-cabinet of the extruder. The 40 and longer L/D extruders are equipped with an additional zone with atmospheric vent opening.

- Variable speed single screw hopper feeder with stirring arm over the screws. Feeder components are equipped with quick locks for easy cleaning, and the whole feeder assembly can easily be slid backward for access to the extruder in-feed opening.

- Practical 2-holes strand die connected to extruder flange with two hinged bolts. The die is made with short distance to screws and minimum internal volume to enable very easy and fast cleaning. Also equipped with easily removable breaker plate in extruder flange, enabling production with or without a screen pack

- For the twins supplied with high corrosion resistant M390 steel, the die is also made from same M390 steel. Further, all barrel modules are done in stainless steel where the barrel inserts and screws are made with M390 steel types.

- 300 bar pressure transducer at screw end, also equipped with a melt temperature sensor. Additionally melt sensors are placed on every second module, connected to digital temperature indicators on the control panel.

- Screws protected by a new sensitive torque limiter mounted in between the motor and the gearbox.

- Modern design with a sturdy sub-cabinet containing all electric and electronic components as well as the optional vacuum pump mounted in designated compartments

- Large clear vision control panel, mounted on a swing arm on the rear of the extruder and containing the following:

- Programmable pressure controller with digital indication of the screw tip pressure.

- Digital melt temperature indicators showing resin temperature at the screw tip as well as at every second module. For the 32 L/D version, there are then totally four melt temperature indicators, and the 40 L/D versions have five of the same indicators.

- Digital RPM indicators for main screws speed as well as feeder screws speed with UP/DOWN scroll buttons to regulate speeds.

- Digital instrument showing screw torque in percent of max torque

- Clear warning lamps for:

- Overpressure at screw tip (depending on your individual set max pressure)

- Cooling water pressure too low

- Clamshell Open

- Motor Overload

- Torque limiter overload

- Feeder overload

- Temperature not reached set value on any of the controllers due for instance broken heating element

An additional control panel is mounted on the sub-cabinet, containing all the digital self-adjusting PID controllers for the barrel, one for each barrel zone and an additional controller for the die. The controllers are equipped with a fail-safe function which will prevent the extruder to start before it has reached the set temperature and which also will stop the extruder if the temperature drops below the preset limit value.

An additional control panel is mounted on the sub-cabinet, containing all the digital self-adjusting PID controllers for the barrel, one for each barrel zone and an additional controller for the die. The controllers are equipped with a fail-safe function which will prevent the extruder to start before it has reached the set temperature and which also will stop the extruder if the temperature drops below the preset limit value.

New Features

Our standard twins are now all supplied with High Torque shafts of the same type as was offered earlier only for the Maxi Compounder. Further, we have added new options as following:

- High wear-resistant screws and barrel insert where the standard nitrided components are replaced with a high wear-resistant steel type from Crucible, USA type CPM9V, and CPM 10V. This version is recommended when the compounding is made with abrasive components such as ceramic powders etc.

- Medium Corrosion Resistant screws and barrel inserts to be used with low corrosion resin types such as PVC. Here the screw elements and barrel inserts will be made in a stainless steel type SUS 440C

- Very High Corrosion Resistant screws and barrel inserts where the elements including screw shafts are made with M390 steel from Germany. This version is specifically designed for compounding of Fluor plastics and other high corrosive plastics. The M390 steel type offers a significant improvement in hardness and thus also wear resistance compared with earlier Inconel types.

- NEW Maxi20Compounder with high torque 11 kW drive and max screw RPM of 1200. Designed with new high torque gearbox which has forced oil lubrication by a gear pump coupled to a large plate heat exchanger for cooling of the oil.

Maximum Production Output with our Co-Rotating 20 mm twin screws extruder type LTE20-40,

with 40 L/D length equipped with 5.5 kW motor drive and 800 screw RPM

| Polymer Type | Melt Flow Index | Maximum Output | % of Maximum | Screw | Barrel temperature range | |

|---|---|---|---|---|---|---|

| (Regular Pellets) | (g/10min) | lb/hr | kg/hr | Motor Power | (rpm) | ° C (starting from in feed zone) |

| LDPE | 20 | 46 | 21 | 83 | 800 | 150 – 180 |

| HDPE | 15 | 59 | 27 | 84 | 800 | 150 – 200 |

| PET* | – | 46 | 21 | 84 | 800 | 280 – 300 |

| Nylon* | – | 33 | 15 | 84 | 800 | 260 – 280 |

| ABS* | 18 | 59 | 27 | 85 | 800 | 220 – 240 |

| GPPS | 8 | 70 | 32 | 71 | 800 | 220 – 240 |

| HIPS | 8 | 72 | 33 | 74 | 800 | 210 – 230 |

| PP | 11 | 39 | 18 | 58 | 800 | 220 – 240 |

| POM | 9 | 66 | 30 | 83 | 800 | 220 – 240 |

| PC* | 19 | 39 | 18 | 85 | 800 | 270 – 290 |